Is It Safe to Cover Fire-Rated Downlights with Insulation?

Fire-rated downlights have become a staple in contemporary building designs, offering not just illumination but also critical safety benefits. However, their installation often raises an important question: Can you safely cover fire-rated downlights with insulation without jeopardizing their fire protection capabilities? Let's explore this essential topic.

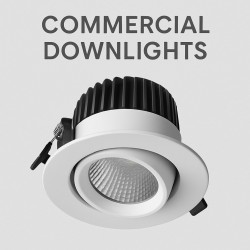

What Are Fire-Rated Downlights?

Fire-rated downlights are specifically engineered to contain fires within the room or ceiling void, preventing them from spreading to other areas of the building. These fixtures are crafted from fire-resistant materials and rigorously tested to meet strict safety standards, typically assigned a fire rating of 30, 60, or 90 minutes.

This fire rating is particularly relevant to the joist construction within load-bearing ceilings. The primary function of fire-rated downlights is to preserve the ceiling's fire rating, as the luminaire's cut-out creates a potential breach in the fire barrier. These downlights undergo comprehensive testing as part of a complete ceiling system by independent specialists, following standards such as EN 1365-2 or BS 476-21. If you're unsure, it's best to request the test report from the downlight manufacturer.

The Insulation Challenge

Insulation is vital for enhancing energy efficiency in homes and buildings. It helps maintain comfortable indoor temperatures by keeping heat in during winter and out during summer, thereby reducing energy consumption and carbon emissions. However, integrating insulation with electrical fittings like fire-rated downlights requires careful consideration to ensure safety.

Navigating Fire Safety Regulations

In the UK, building regulations are stringent when it comes to the installation of electrical equipment, including fire-rated downlights, to ensure occupant safety and minimize fire risks. For commercial applications, new constructions, and rental properties with living spaces above, fire-rated downlights are mandatory. The Electrical Safety Council (ESC) advises using fire-rated downlights in all installations, regardless of the application. Complying with these regulations helps maintain the integrity of the fire-resistant barrier.

Best Practices for Installation

To safely install fire-rated downlights with insulation, adhere to these best practices:

Follow Manufacturer Guidelines

Always consult the manufacturer's instructions for both the downlights and the insulation. Manufacturers typically provide detailed installation guidelines for their products when used with insulation. These instructions can vary based on the type of downlight, insulation material, and fire rating requirements, so it's crucial to verify each time.

Maintain Adequate Clearance

Adequate clearance is essential to prevent overheating, ensure proper air circulation, and maintain fire rating standards. Some downlights are designed to allow insulation directly on top, while others require more clearance to facilitate airflow and heat regulation.

Choose the Right Insulation

Opt for non-combustible insulation materials that can withstand high temperatures. Mineral wool, glass wool, and cellulose fiber insulation are excellent choices as they meet safety standards and pose minimal fire hazards. Avoid foil-backed insulation, as it can create thermal barriers that may cause the downlight to overheat.

Note: The insulation type must be specified in both the joist manufacturer’s safety report and the downlight's fire-rating certification. Downlights are only fire-rated for the specific type of ceiling tested and must be tested alongside the insulation to meet regulations. This also applies to joist construction. Fire test reports can be obtained from manufacturers.

Seek Professional Guidance

When in doubt, consult qualified professionals, such as electricians or building inspectors, to ensure compliance with safety regulations.

In summary, while it is possible to cover fire-rated downlights with insulation, it is imperative to follow best practices and adhere to safety regulations to avoid fire hazards. By consulting manufacturer guidelines, maintaining proper clearance, choosing suitable insulation, and seeking professional advice, you can achieve a safe and effective installation.